Client: Leading manufacturer of mobile robots and AGVs

Industry: Industrial Automation / Robotics / Logistics

🎯 The Challenge

In dynamic warehouse environments, pallets are often misaligned or placed unevenly in pallet nests. This posed a significant challenge for autonomous forklifts, leading to operational delays, handling errors, and safety risks.

🧠 The Goal

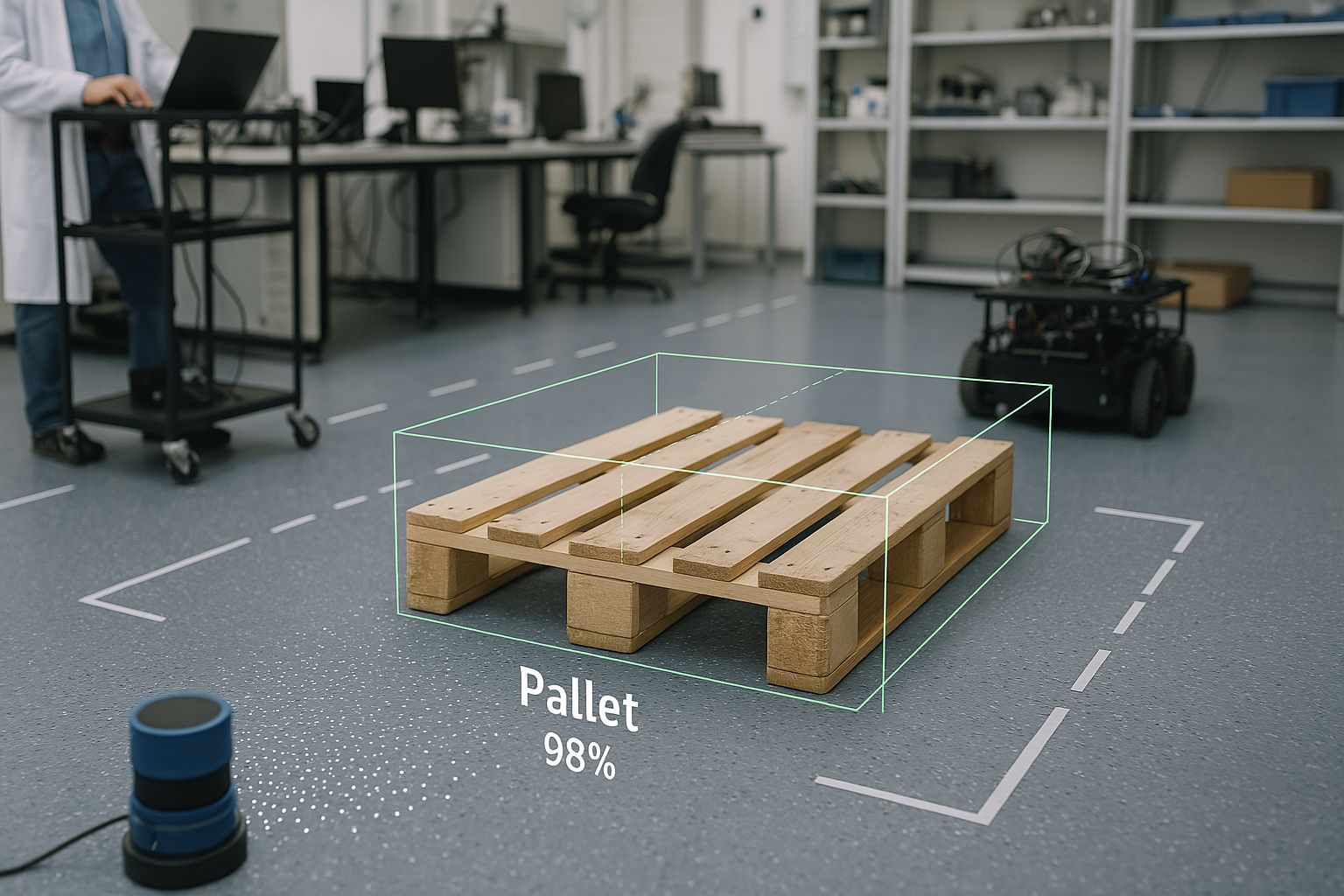

Develop a reliable AI-powered vision system capable of detecting and localizing pallets accurately – even when their position is unpredictable or irregular.

🛠️ Our Solution

We implemented a custom-built computer vision system, integrated directly with the client's AGV platform. Our approach combined:

- Real-time pallet detection in variable industrial conditions

- Robust localization, regardless of placement or angle

- Seamless integration with autonomous forklifts

Thanks to advanced AI algorithms and industrial-grade vision pipelines, the system consistently identifies pallet positions with high accuracy.

📊 The Results

✅ 95% reduction in warehouse accidents – AI-based detection minimized risks related to misaligned pallet handling

✅ 35% cost savings – Outsourcing AI development proved significantly more cost-effective than building an in-house AI team

✅ Higher operational efficiency – Faster pallet detection led to smoother

AGV cycles and safer workflows

🚀 Ready to power your operations with AI?

If you're planning a project in AI/ML, computer vision, or autonomous logistics, we’re here to help.