Implementation stages:

1. Zero audit:

-

A thorough analysis of your warehouse and logistics processes to identify areas that can be automated.

-

Identification of key parameters such as goods flow, warehouse structure and performance requirements.

2. Site visit:

-

A visit to your company to assess your warehouse infrastructure and learn about your specific challenges.

-

Measurements and creation of detailed warehouse maps.

3. Computer simulation of processes:

-

Development of a virtual model of your warehouse and simulation of various work scenarios using AGV systems.

-

Optimize routes and system configurations to ensure maximum efficiency.

4. Financing:

-

Advice on various financing options, including leasing, purchase and grants.

-

Assistance in preparing applications for financing and negotiations with leasing companies.

5. Pre-implementation tests:

-

Testing the AGV system in a simulated warehouse environment to detect and correct potential problems.

-

Refinement of system configuration and operating procedures.

6. Training:

-

Providing comprehensive training for your employees in the operation and maintenance of the AGV system.

-

Providing knowledge about safety, maintenance and troubleshooting.

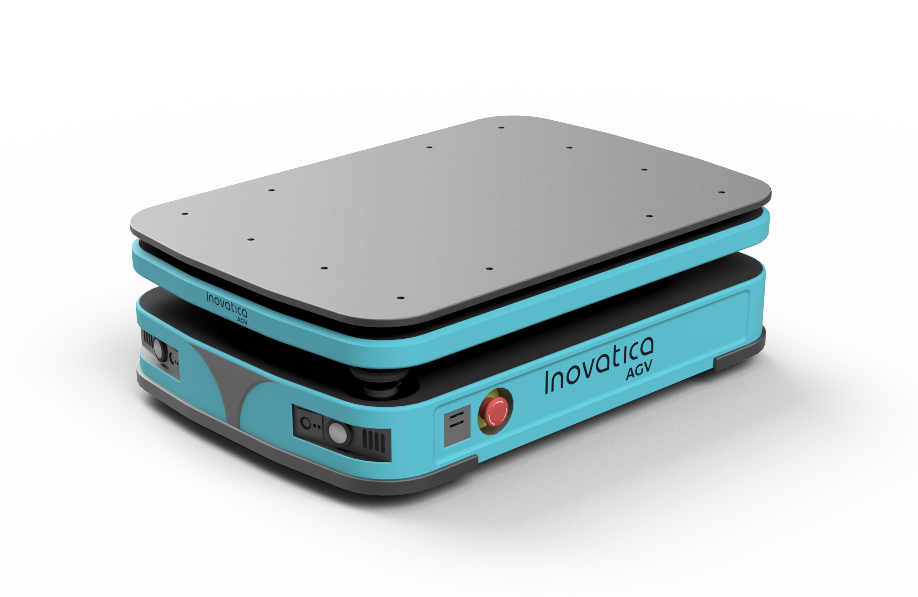

7. Implementation:

-

Assembly and installation of an AGV system in your warehouse.

-

System integration with existing warehouse and ERP systems.

8. Maintenance, warranty service:

-

Offering comprehensive service and maintenance services to ensure optimal operation of the AGV system.

-

Availability of 24/7 technical support in case of problems.

Zostaw nam kontakt i sprawdź ile możesz zyskać

Contact form Additional information:

-

We also offer modernization services for existing AGV systems.

-

We adapt our solutions to the individual needs of each client.

-

We cooperate with leading producers of AGV systems in the world.