One of the main reasons autonomous forklifts cannot match human operators is safety standards, such as ISO 3691-4:2023. These regulations restrict the speed of mobile robots in designated zones, such as restricted areas, where the speed of autonomous forklifts is limited to 1.2 m/s. These limitations aim to ensure workplace safety and prevent collisions with humans or other objects.

Another determining factor affecting the performance of autonomous forklifts is the definition of the internal transport process. While AGV/AMR vehicles may achieve performance close to operators when traveling along long straights, they lose significant time during loading and unloading operations in areas where humans move. The solution to this problem is the allocation of isolated zones for AGV/AMR vehicles' movement, where norm recommendations allow for increased speed of these vehicles.

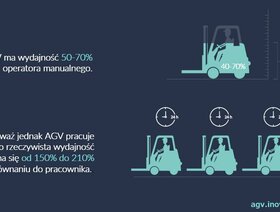

Although autonomous forklifts may not be as fast as human operators, their primary justification is operational efficiency measured over a 24-hour period. For companies operating shifts, AGV/AMR vehicles can replace 2 or 3 traditional forklift operators, leading to a significant increase in operational efficiency. In the case of 2 or 3-shift work, the operational efficiency of AGV/AMR vehicles can range from 150 to 210% of traditional forklift operators' work.

Are you convinced to implement AGV/AMR solutions in your company? If so, we invite you to contact us, where we offer a wide range of products and experience in implementing AGV/AMR vehicles. If you still have doubts, we are happy to discuss any issues related to the implementation of these innovative solutions with you.