Cost reduction and CO2 emission reduction

As global environmental awareness continues to grow and concerns about carbon dioxide emissions and worker safety increase, the industry must seek innovative solutions that simultaneously contribute to environmental protection and improve safety. Autonomous forklifts have become a crucial element of this strategy, offering numerous benefits to both the environment and businesses.

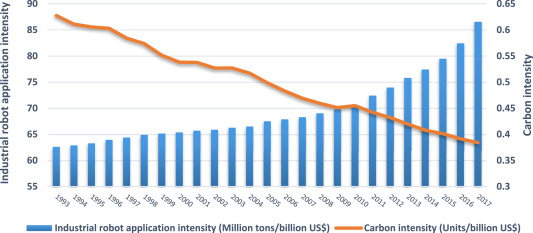

Companies particularly appreciate the lower maintenance costs of mobile robots compared to traditional manually operated forklifts. Key advantages include route optimization, reduced servicing costs, extended equipment lifespan, and reduced waste. Implementing robots leads to increased efficiency while reducing the intensity of CO2 emissions.

Autonomous forklifts as a solution

Autonomous forklifts employ advanced technologies, such as laser navigation, artificial intelligence, machine learning, and various sensors, to significantly reduce operational costs and CO2 emissions in the industry. Here are some ways they achieve this:

- Optimized Routes: Autonomous forklifts are programmed to select the most efficient transport routes within warehouses and production areas. They utilize advanced algorithms to avoid traffic congestion, thereby reducing working hours and CO2 emissions.

- Lower Maintenance Costs and Longer Lifespan: Thanks to precise maneuvering and constant speed control, autonomous forklifts maintain high accuracy throughout their operational life. Lower servicing costs and an extended lifespan translate into savings and a reduced environmental footprint.

- Reduced Material Loss: Precise maneuvering and collision avoidance help minimize material losses and damage during transport. This results in reduced waste production and material consumption.

- Intelligent Energy Management: Autonomous forklifts can be programmed to maintain optimal operating parameters, leading to more efficient energy use and lower CO2 emissions.

Source: Technology in Society Volume 70, August 2022, 102034

, www.sciencedirect.com/science/article/abs/pii/S0160791X22001750

New Mobility Congress

The topic of emission reduction and the effective use of electric vehicles was also a significant focus at the New Mobility Congress (NMC) held in Łódź. Over three days, more than 3,000 representatives from the e-mobility sector from around the world discussed key trends and challenges related to the transportation sector's transformation. With over 150 partners and exhibitors presenting the latest zero-emission technologies across a 13,000-square-meter exhibition area at EXPO Łódź, the overarching conclusion was clear: Poland must seize the historical opportunity presented by the development of electromobility for its economy.

Inovatica AGV actively participated in the event, showcasing the role that autonomous vehicles can play in emission reduction and efficiency improvement in logistics. Experts at NMC emphasized that emissions from machinery are 2 to 6 times higher than those generated by cars. Electrifying the non-road mobile machinery (NRMM) sector will bring benefits not only to society as a whole but also to the workers operating these machines. Initially, zero-emission specialized machines will be implemented in closed areas such as mines and loading ports. Additionally, technologies based on hydrogen fuel cells can play a significant role in the decarbonization of this sector.

Safe internal transportation

Human errors are a leading cause of work stoppages and accidents in warehouses. Autonomous forklifts, operating based on computer programs, eliminate the risk of human errors, such as collisions or damage. Research confirms that human errors account for a significant portion of unplanned production stoppages. Why is this important for businesses?

• 23% of all unplanned production downtime results from human errors (research conducted by GE Digital). • $150 million is the estimated cost of losses in intralogistics due to human errors (study conducted by Amazon Web Services in 2017, covering companies listed on the S&P index).

Conclusion

Autonomous forklifts represent an innovative tool that supports the goals of reducing CO2 emissions in the industry while simultaneously enhancing workplace safety. Their ability to optimize routes, precise maneuvering, and efficient energy management contribute to reduced CO2 emissions. The elimination of human errors and the assurance of constant attention and safe behavior translate into improved workplace safety. As this technology continues to evolve and becomes more accessible, autonomous forklifts are expected to play an increasingly significant role in achieving sustainability and efficiency goals in the industry.

Photos source: https://pspa.com.pl