Below is the translated version of the article in English, preserving its original structure and headings: ---

Declining Availability of Forklift Operators in Poland

The Polish job market is facing growing challenges related to the decreasing availability of forklift operators. This phenomenon is driven by several key macroeconomic trends:

1. Low Unemployment Rate: For several years, Poland has maintained a low unemployment rate, which stood at just 5.2% in 2023. While this indicator is generally favorable for the economy, it also means that it is increasingly difficult to find qualified workers for forklift operator positions.

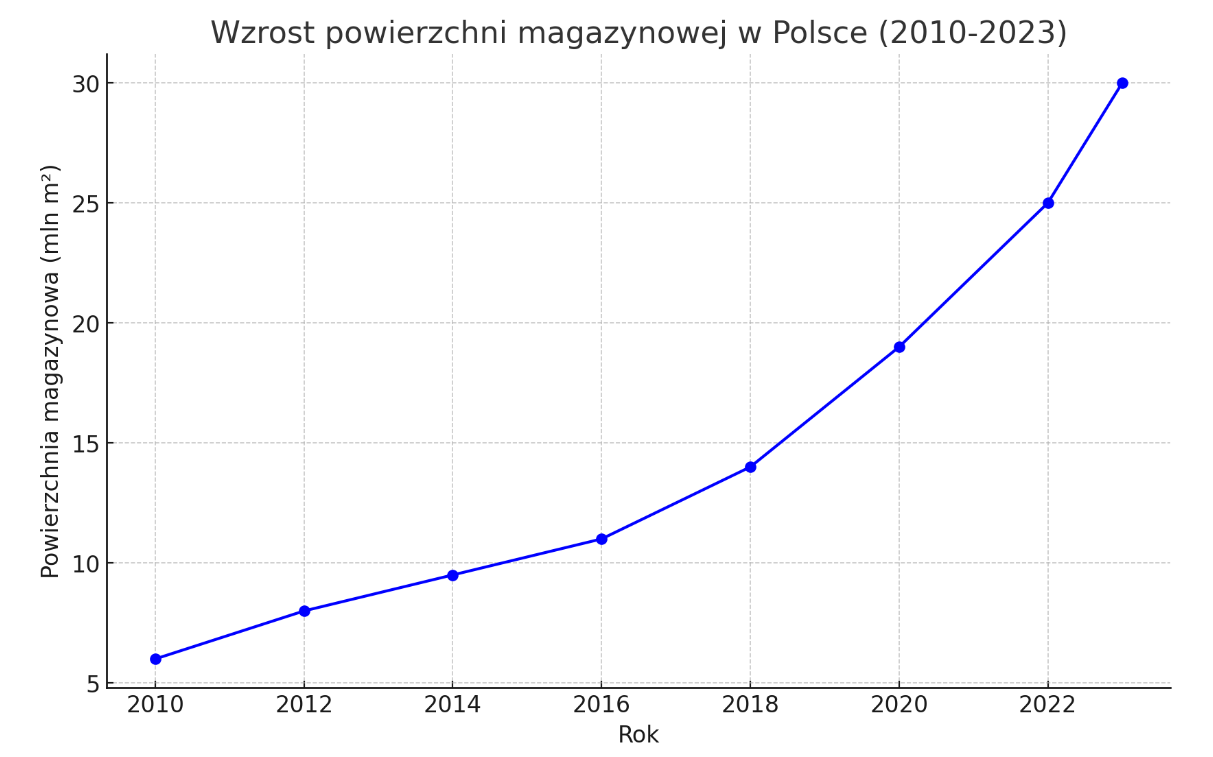

2. Growth in Warehouse Space: With the rapid development of the logistics sector, warehouse space in Poland has already exceeded 30 million square meters. This expansion creates a huge demand for forklift operators, who are essential for managing the increasing volume of goods in warehouses.

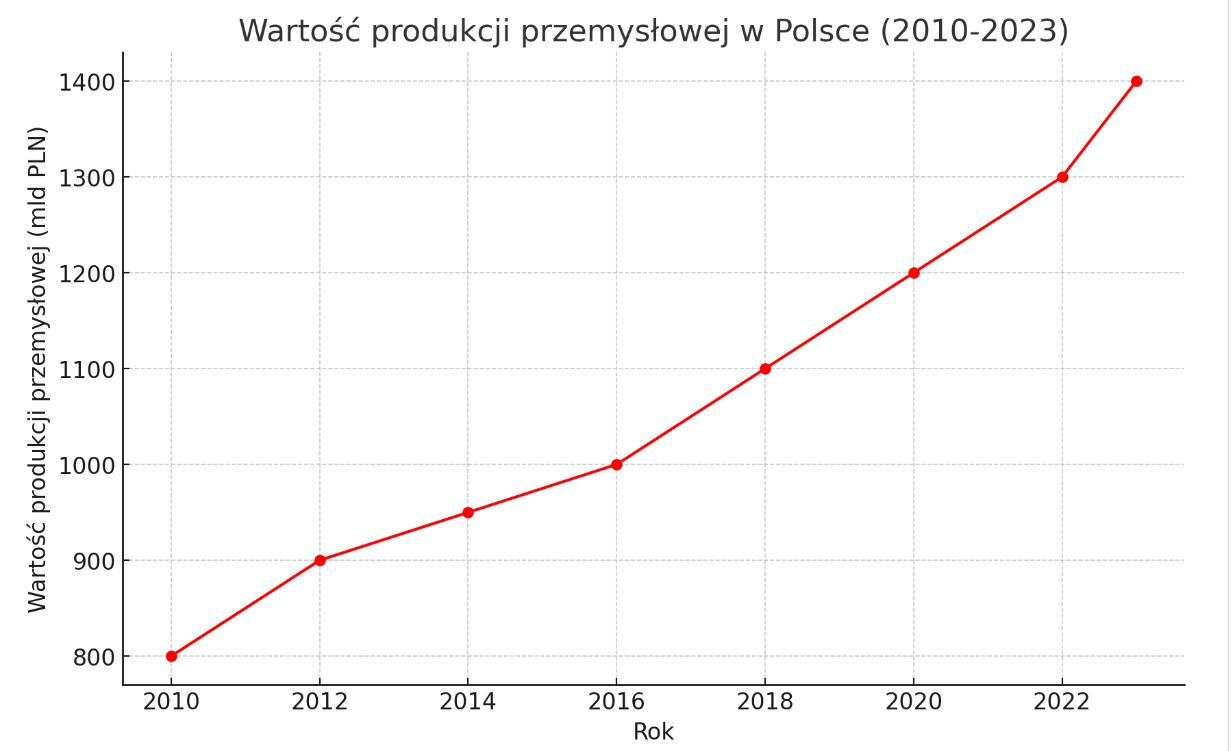

3. Growth of the Manufacturing Sector: The value of industrial production in Poland has also been steadily rising, reaching around 1,400 billion PLN in 2023. This growth requires an increasing number of workers to operate production lines and warehouses, further exacerbating the shortage of operators.

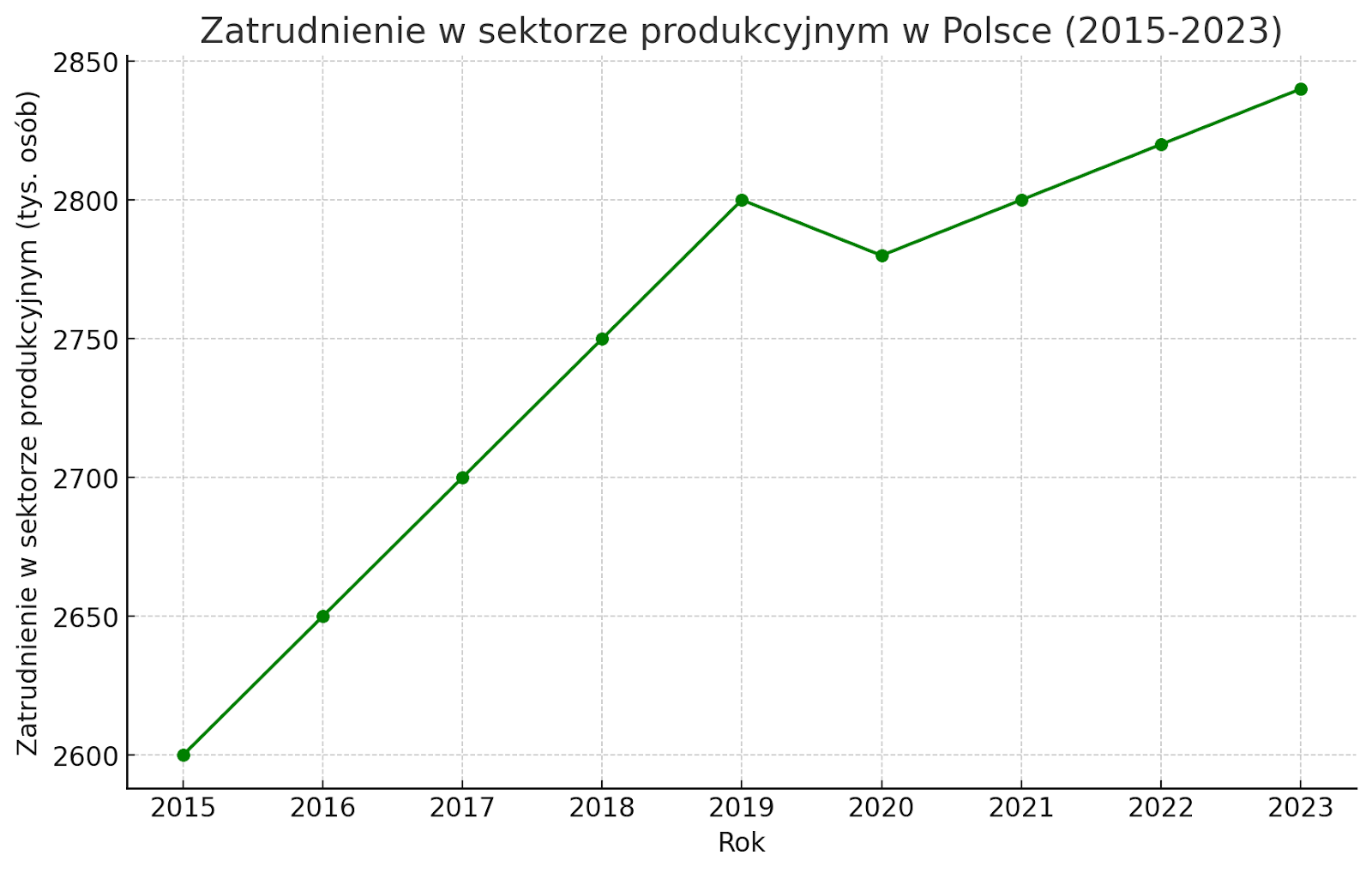

4. Increase in Employment in the Manufacturing Sector: Employment in the manufacturing sector rose to about 2.84 million people in 2023. However, despite the increase in overall employment, the number of available forklift operators does not keep pace with the growing demand.

5. Rising Wage Costs: The growing demand for forklift operators has led to an increase in their salaries, which averaged 5,720 PLN gross in 2024. The law of supply and demand is ruthless here – the lower the availability of workers, the higher the cost of employing them.

Conclusions

All of the above trends clearly point to upcoming problems regarding both availability and rising costs of forklift operators in Poland. In the face of these challenges, the only reasonable solution is to automate and robotize internal transport. Automated Guided Vehicles (AGVs), which can replace human labor, provide an answer to these problems. The company Inovatica AGV offers modern solutions for internal transport automation, which can revolutionize the way warehouses and production are managed. For more information, visit the Inovatica AGV website.

What Happens If You Don't Implement Automation?

Failing to introduce automation in the face of the above challenges can lead to several negative consequences for companies:

- Reduced Competitiveness: Companies that do not invest in automation may be overtaken by competitors who adapt more quickly to new market conditions.

- Higher Operating Costs: Rising wage costs and recruitment difficulties for operators can significantly burden a company’s budget, impacting its profitability.

- Lower Quality of Products and Services: A shortage of employees can lead to delays, errors, and lower product quality, which can result in the loss of customers.

- Risk of Losing Customers: Customers who do not receive ordered goods or services on time or at the expected quality level may choose to work with competitors, directly jeopardizing the company’s future.

Do not wait until these problems become a reality – invest in automation today and secure your company’s future.